Half Cat Static Test 2 - January 25, 2021

Failure (combustion chamber exploded during firing)

Partial data acquired

Changes from previous test: Conical interface between piston and lower tank bulkhead to eliminate residual fuel volume, CHAMBERSAFE thermal liner

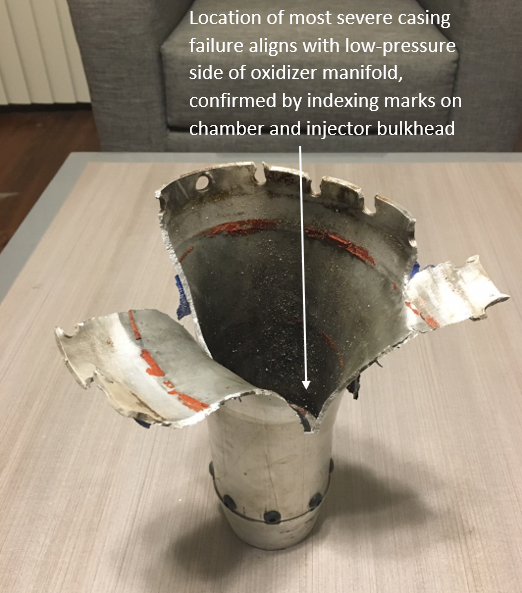

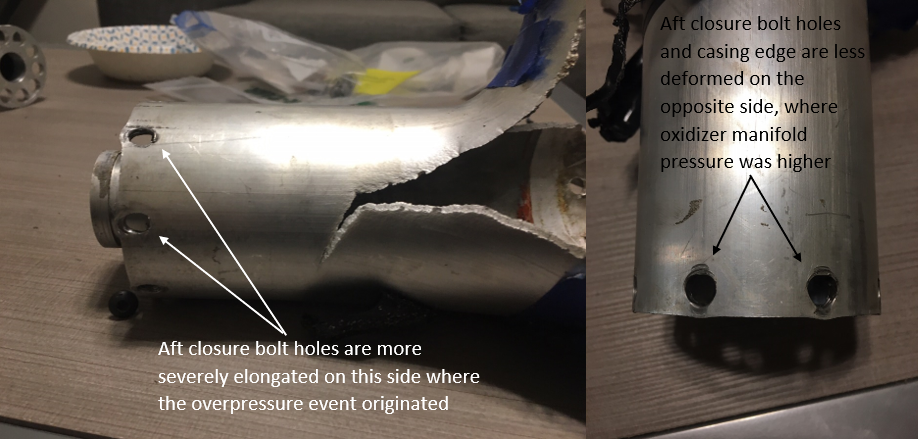

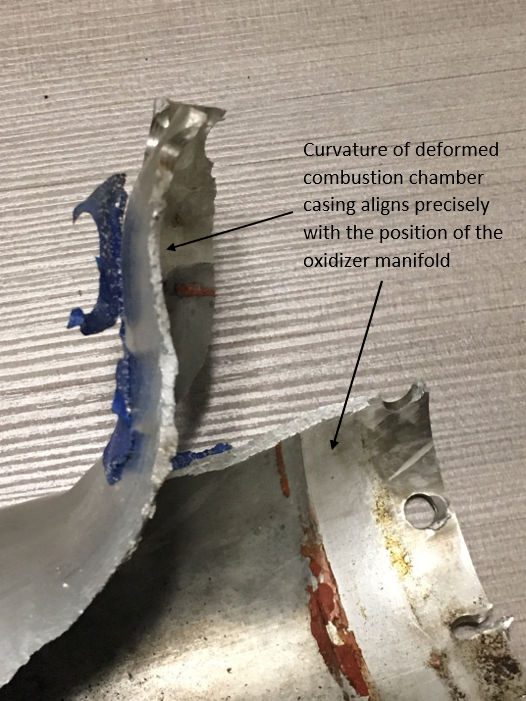

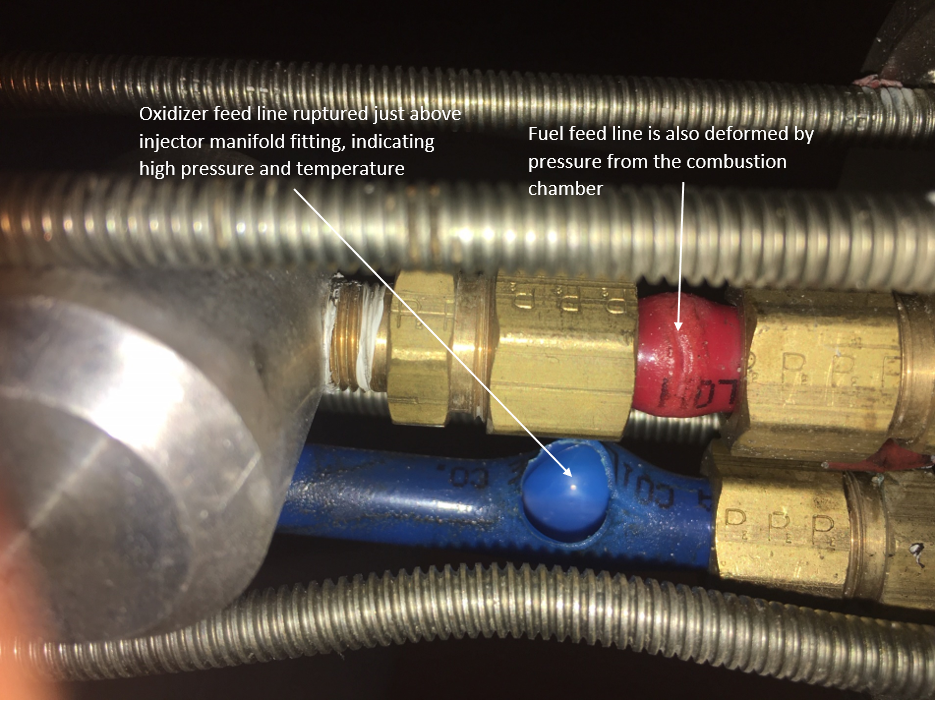

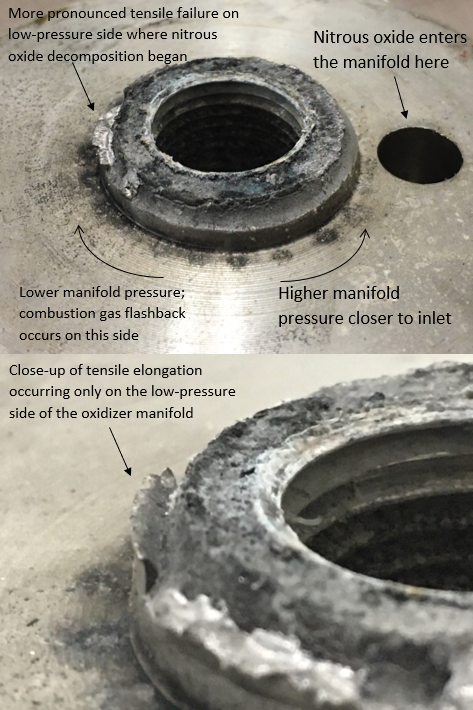

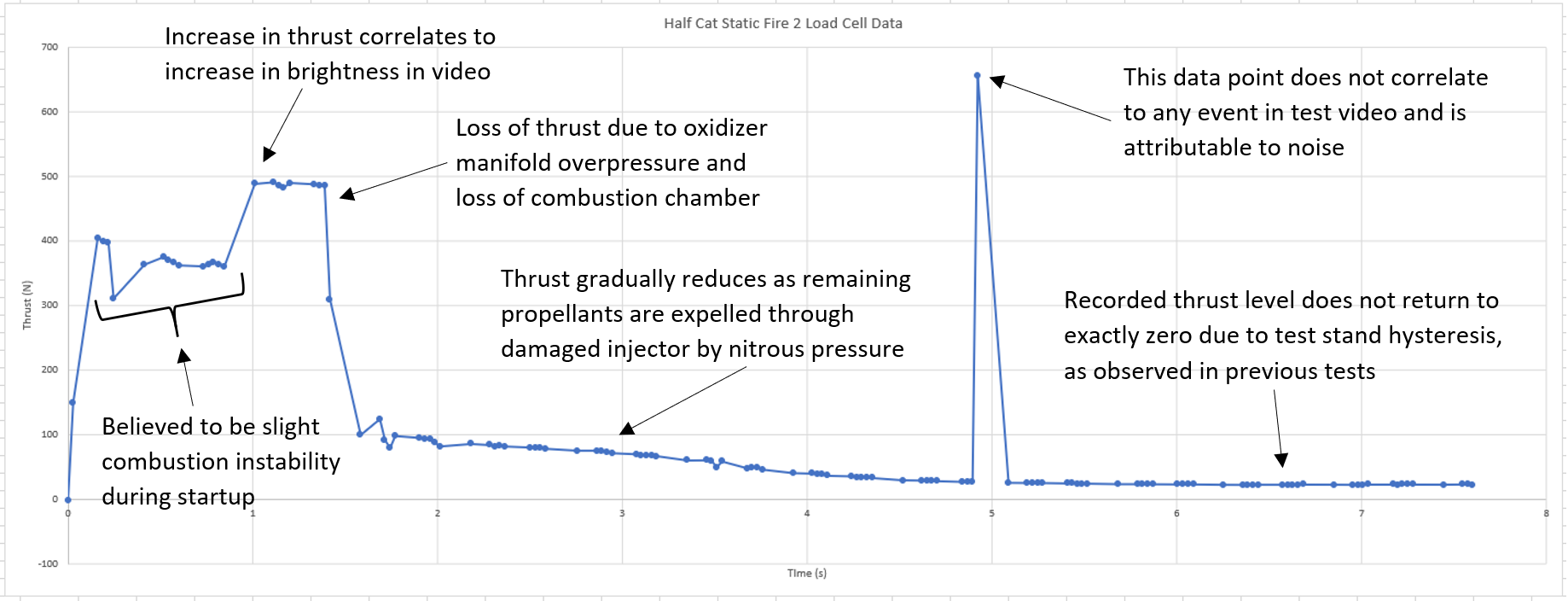

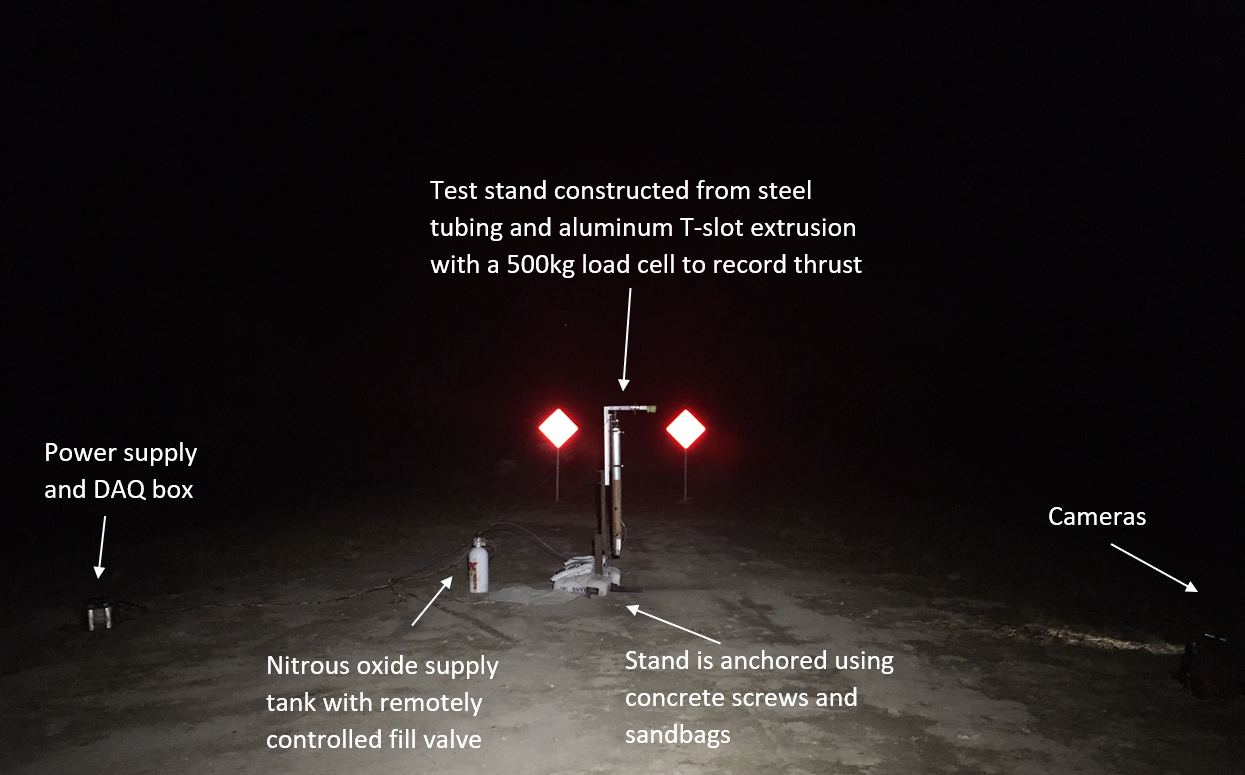

Unfortunately, due to a recycled firing attempt, our good cameras died and the above is the best video available. On this occasion, one filling cycle had already been attempted but was aborted just before ignition due to the oxidizer fill tube disconnecting at the end of the fill. As a result, the supply tank was now only half-full and significantly colder - and therefore lower pressure. When filled a second time and ignited, the lower tank pressure meant that the combustion chamber pressure could become greater at a certain point on the injector and reverse flow through one or more orifices, forcing hot gas into the oxidizer manifold and causing nitrous oxide to again decompose explosively.

(See detailed failure analysis below)

Following this test, a new combustion chamber and injector were fabricated along with a “new” nozzle to replace the graphite ones which had both been broken in tests 1 and 2. The nozzle was made for the original iteration of the engine, but since it was the only one left on hand it became the replacement for test 3. The CHAMBERSAFE liner was not properly tested this time, as it shattered when the injector detonated.

The results of test 1 and 2 - that a decomposition event and explosion could occur on both sides of the plumbing without propagating to the other side - led to the realization that the nylon tubing of the propellant feed lines act as burst discs; it pops quite easily under unexpected stress. This will be important later.

Drop-off in thrust correlates to unexpected rapid loss of combustion chamber