1Cat/3

THRUST: 110 LBF

FUEL: ISOPROPANOL

OXIDIZER: NITROUS OXIDE

BURN TIME: 1 SECOND

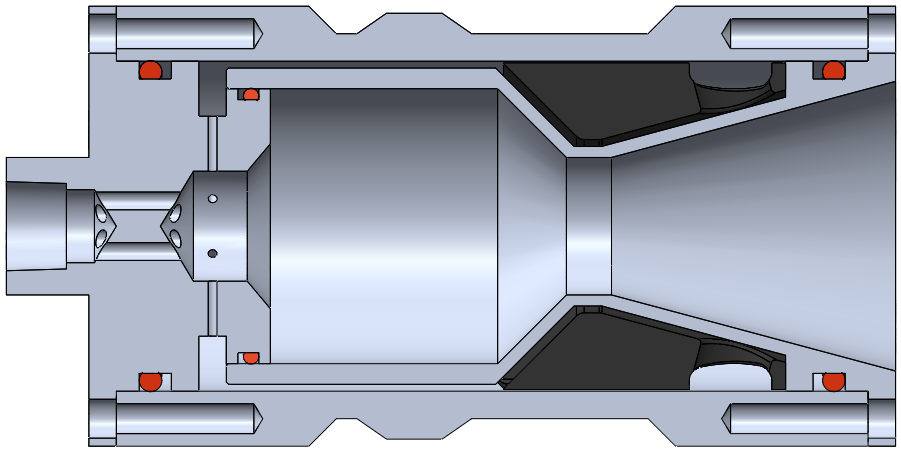

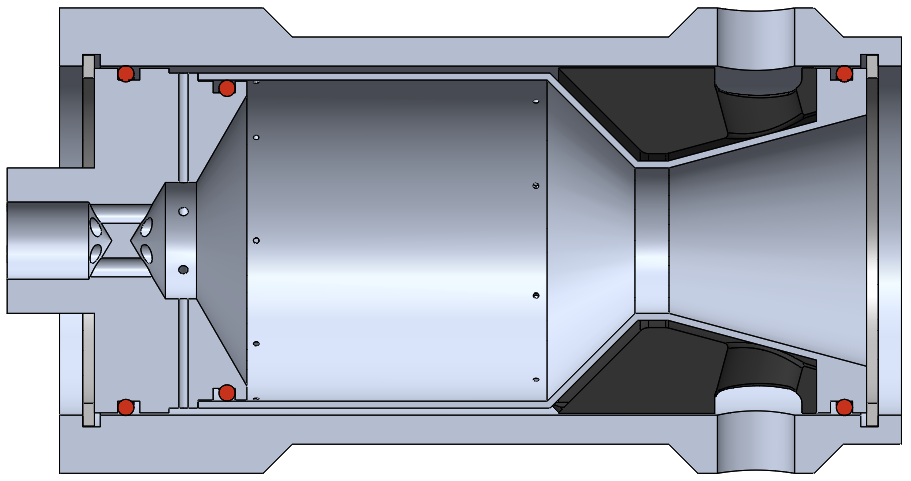

1Cat/3 was a departure from other Half Cat Rocketry designs at the time (late 2021). It is an actively cooled combustion chamber with a saddle-jacket style regenerative loop with no channels (just an annulus), film cooling (the extra sets of holes in the chamber), and a grossly low mixture ratio (~2.0) to reduce temperature. All holes were drilled with 3D printed jigs and a drill press + mill vise.

The most familiar type of regeneratively cooled liquid engine chamber consists of a series of milled channels, or a bundle of tubes brazed together. The reasoning at the time was that an inefficient but functional cooling jacket can be achieved by a single annulus surrounding the combustion chamber, part of which must be formed by saddle-shaped 3D-printed pieces that are installed around the nozzle throat. The downside to this design is that the annulus must be rather small, <1/32” gap, to yield even moderately high flow velocities, which is necessary for cooling the chamber.

All machined components were made from 6061-T6 aluminum. The initial goal was to survive a short firing, which it accomplished, followed by longer duration burns. Given the short burn, in combination with likely low combustion efficiency, it not surprising that the chamber survived intact, though it is uncertain if it would have lasted longer. Further testing was attempted, but no ignition was ever achieved due to inadequate igniters. The test article was eventually retired, due to its poor design being superseded by subsequent chambers such as Tabby 1.

Hardware

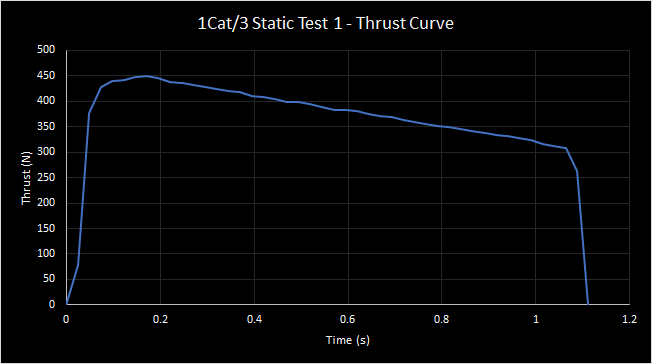

Static Test 1 - 11/20/21

Iterations

1Cat/3A

The first manufactured prototype of the engine had a bolted flange for retention and a thicker wall; after some debate, it was determined that this version would not be fired in favor of a thinner-walled chamber.

1Cat/3B

The second iteration was never completed. The interior walls were to be 0.030” thick, which proved to be too thin to machine on the lathe, so it was abandoned. The jacket and injector were kept for the next version.

1Cat/3C

This variant of the chamber uses snap rings for ease of retention and manufacturing. The interior wall is 0.050” thick with two rows of nine film cooling holes, one at the top of the chamber and one just before the convergent section of the nozzle.